- The Future Is NEUTRAL is strengthening its capabilities in the collection, processing, and recovery of End-of-Life Vehicles (ELVs) with the opening, before the end of the year, of a Dismantling Center at the Flins Refactory (Yvelines, France), with a capacity of 7,000 vehicles per year.

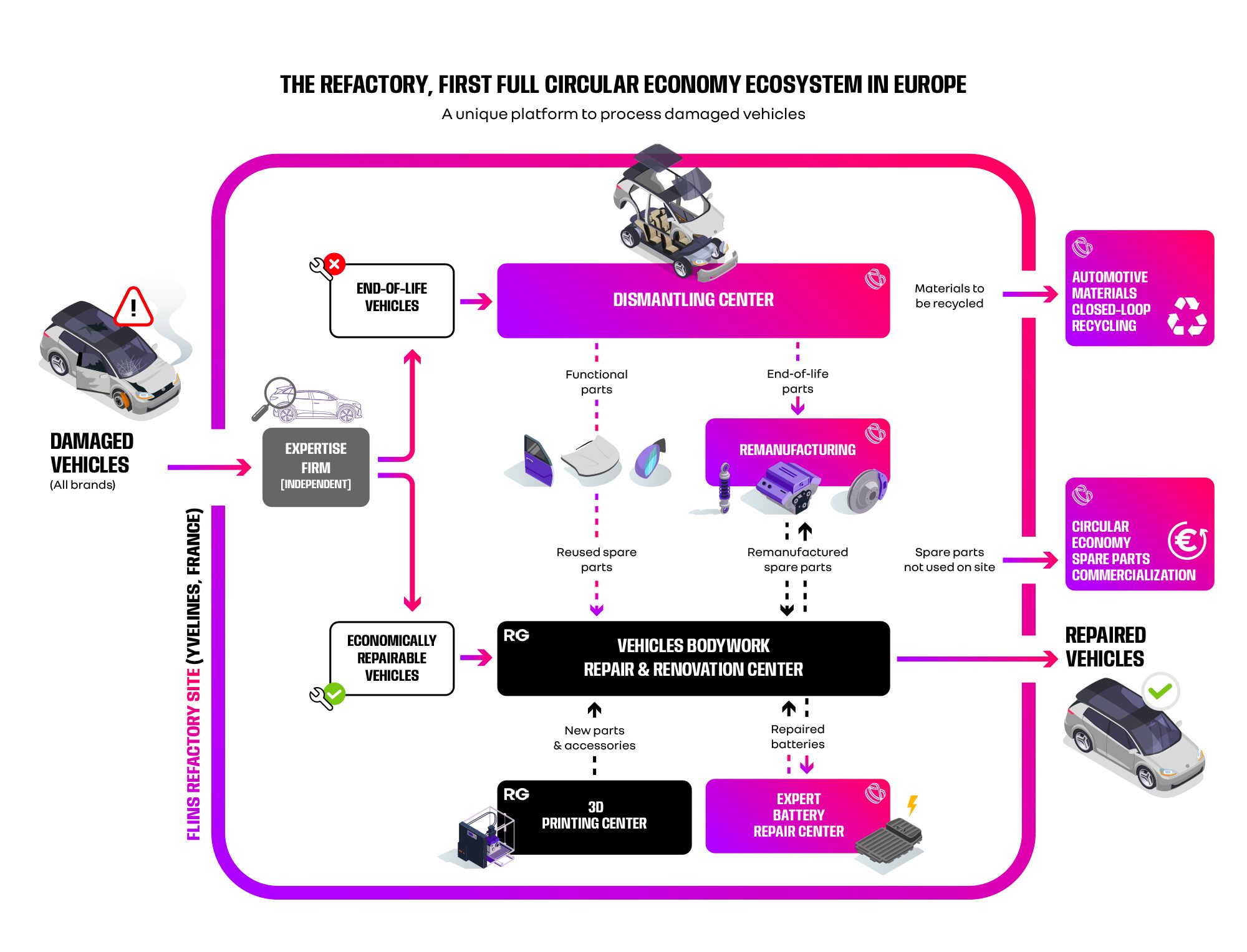

- This Dismantling Center will complement the circular economy ecosystem established at the Refactory, making it a unique platform in Europe that brings together all the necessary expertise for processing damaged vehicles.

- Thanks to an industrialized process, the Flins Dismantling Center will be able to extract more than 25 parts per vehicle and process over 14 different materials for recycling.

June 6, 2025 – The Future Is NEUTRAL continues to strengthen its position across the automotive circular economy value chain by expanding its capabilities in the collection, processing, and recovery of End-of-Life Vehicles (ELVs). These essential activities within the circular economy value chain help supply reused parts and materials to be recycled.

A Dismantling Centre will complete the circular economy ecosystem developed by The Future Is NEUTRAL at the Flins Refactory, and will create, in a first phase, 20 jobs. Upon its launch, it will benefit from INDRA’s full expertise in deconstruction engineering and training in ELV processing professions. The center will then be operated by GAIA, a subsidiary already established at the Flins Refactory.

« ELVs represent a key raw material for us, enabling the automotive sector to be supplied with the parts and materials it needs to operate—without depleting natural resources. The Flins Dismantling Center not only strengthens our ELV processing capabilities but also allows us to establish short closed-loop by feeding into our other circular economy activities based at the Refactory in Flins. This meets the demands and expectations of various clients, including repair professionals and insurers, in terms of performance, service quality, and environmental standards. »

Xavier Kaufman, Chief Business Officer, The Future Is NEUTRAL and VP, Refactory

A Dismantling Center Designed for Optimal Efficiency

The Flins Dismantling Center will be equipped with a range of expertise enabling it to:

- Industrialize deconstruction, with a 7-station line capable of dismantling 7,000 ELVs per year, using a process that meets the highest standards in safety, ergonomics, and environmental requirements.

- Assess ELVs and maximize their recoveryby optimizing the extraction of reusable parts (over 25 parts per ELV) and recyclable materials (over 14 materials processed and recycled).

- Receive vehicles 24/7.

- Manage on-site vehicle storage.

- Handle the administrative destruction of ELVs and ensure traceabilityof extracted parts and materials.

- Process all types of vehicles, including electric vehicles, by leveraging the advanced diagnostic capabilities of the Battery Repair Expert Center operated by GAIA in Flins.

- Manage the reuse of parts, including sorting, protection, storage, photography, and online listing—particularly on the partner platform Opisto (with a storage capacity of 50,000 parts references).

The Refactory, the First Comprehensive Circular Economy Ecosystem in Europe

The Refactory brings together on a single site all the activities required to process damaged vehicles.

At the heart of this ecosystem, the Dismantling Center will operate in full synergy with the site’s various activities:

- on-site deconstruction of vehicles that are technically or economically irreparable, in coordination with the vehicle repair activities (“the bodywork factory”)

- supply of reused parts to the damaged vehicle repair activities (“the bodywork factory”) and the used vehicles reconditioning (“the renew factory”)

- supply of repairable parts to the parts repair department

- supply of components intended for remanufacturing (The Remakers)

- supply of materials for recycling to support closed-loop systems (GAIA)

- diagnosis and recycling of batteries, drawing on the expertise of the Battery Repair Expert Center in Flins (GAIA)